When I bought the Golding Jobber № 8 letterpress from Bill and Gertie Campbell, Bill generously spent a couple of hours with me showing me some of the trickier bits of using it.

One of the things he taught me is how to print envelopes. Because of the way they’re constructed, printing on envelopes often means printing on different thicknesses of paper at the same time. If you just print as you normally would, the impression will be uneven because the pressure will be uneven on different areas.

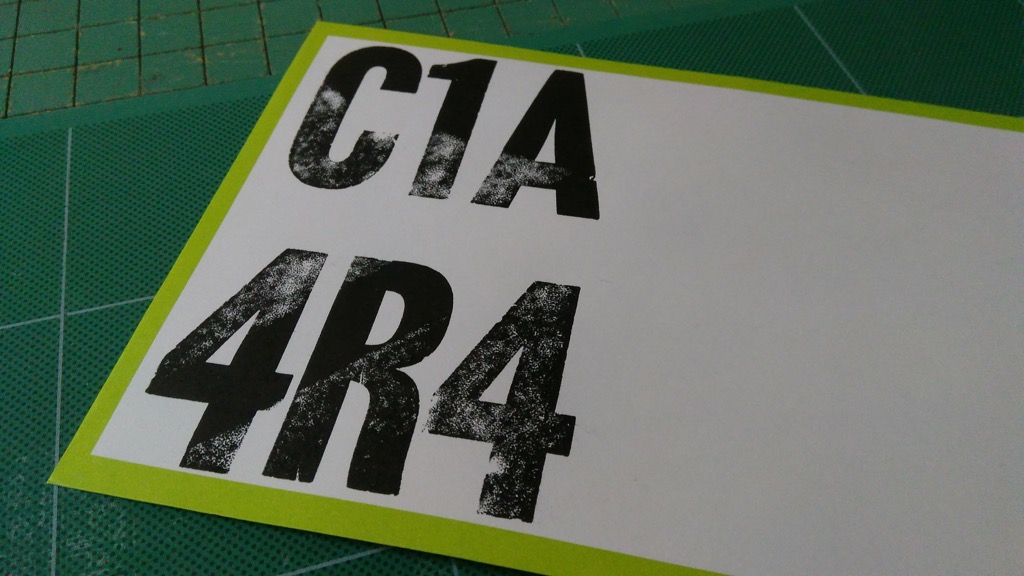

You can see the result in this first print of a C1A 4R4 envelope I printed today:

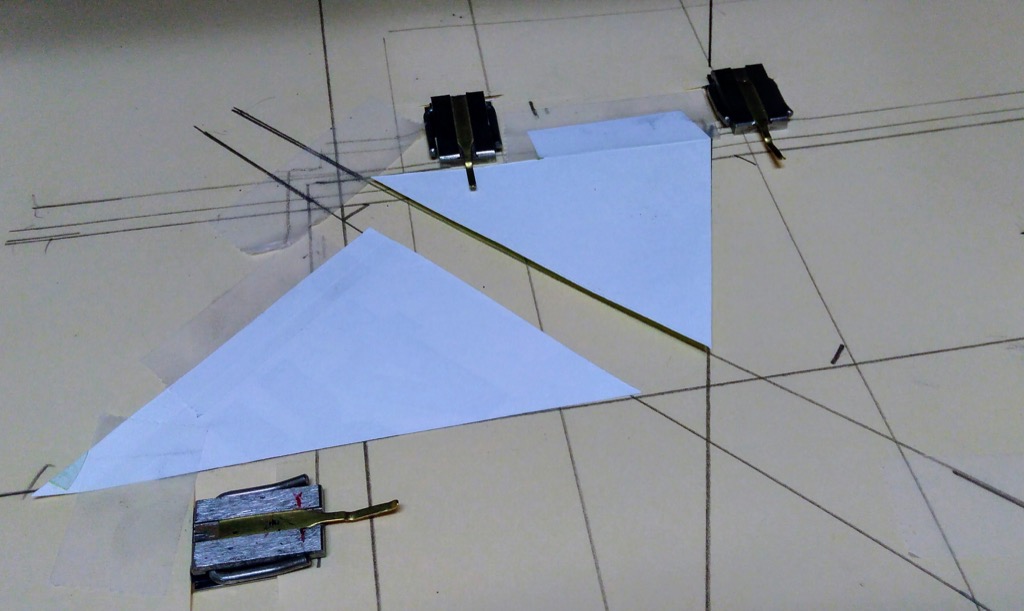

What Bill showed me is how to construct a sort of paper “shim” under the envelopes so that everything ends up being the same thickness when printing. To make the shim, I took the envelope I test-printed, and chopped it up with a knife, using the print as a template for the areas that needed buttressing. The result looked like this:

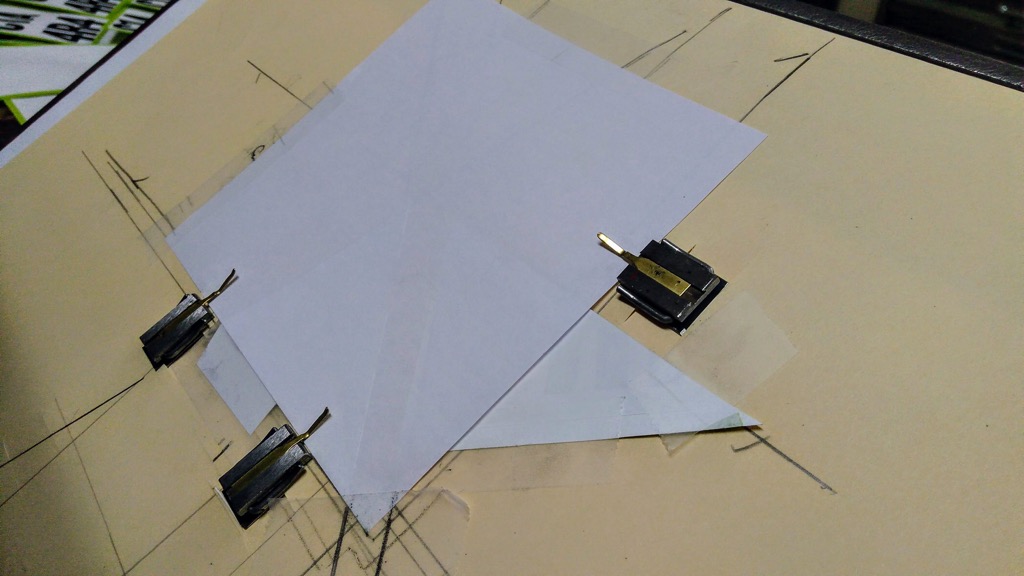

I covered the shim with a layer of paper to avoid it getting caught up in the envelopes while printing, ending up with this:

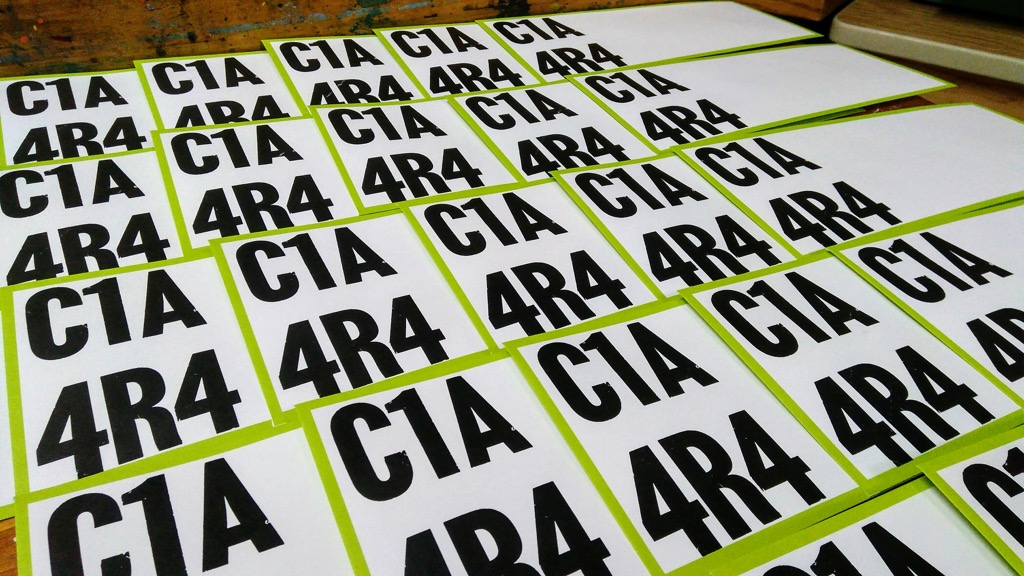

With the shim in place, the envelopes printed cleanly across the entire surface:

I’ve got one more run to take at these envelopes, printing a line, in red, between the C1A and the 4R4; I’ll do that once the black has dried.

I am

I am

Comments

looking good!

looking good!

Add new comment