The opening section of The Young Job Printer contain a very useful glossary. In particular, three terms have served me well today:

Planer.—A smooth block of hardwood used for leveling the surface of type-forms after they have been imposed. The planer is laid on the face of the type and then tapped gently with the mallet.

Proof.—An impression taken from a form before it is sent to the press. The proof is read and compared carefully with the copy, the errors marked on it, and then given to the compositor to correct. After the matter or the form has been corrected, a second proof is taken. This is again read by copy, and should there be any errors found, another proof or revise is taken. The last proof, on which there are no errors discovered, is called a revise.

Proof Planer.—A planer covered with felt cloth, used for taking what is called a stone-proof. The form as it lies on the stone is inked and a piece of dampened paper laid carefully on top. Then the proof-planer is laid down carefully and tapped with the mallet, until a good impression is secured.

From these three definitions I was able to concoct a method for pulling a “proof” of the first sentence of Anne of Green Gables without messing about with the press (which saves a lot of cleanup).

First I rolled out some oil-based ink onto a piece of plexiglass with Speedball roller. I then rolled the ink over the type. Next I spritzed a fine mist of water out of an old Windex bottle onto a flat surface; I then laid a sheet of white bond paper into the mist so that it became a “dampened paper.” I took this sheet of paper and placed it, less-wet-side-down, into the inked type. Finally, I placed a piece of think felty fabric over the paper, and over that a piece of plywood – together they formed a makeshift “proof planer” – and rolled a clean roller over the plywood.

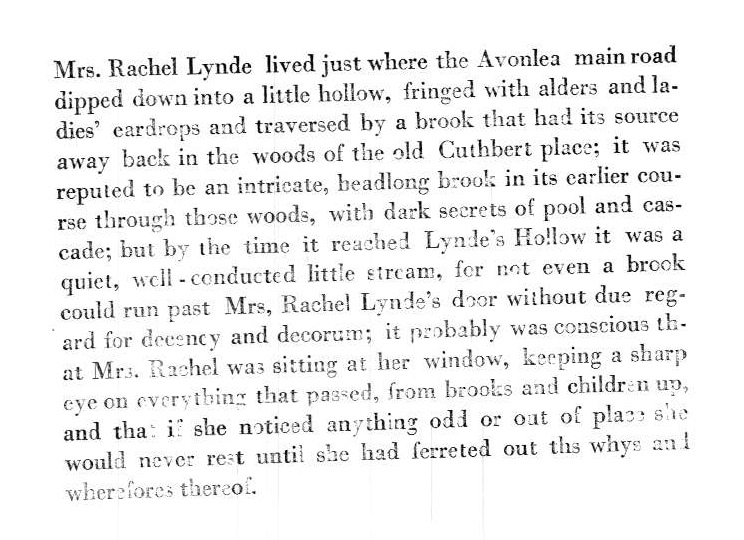

The result was this:

It’s not perfect. But then again it’s not supposed to be: it’s only a proof. And it’s just about clear enough for me to actually “proof” the copy before making any corrections and then moving to print on the press.

I am

I am

Add new comment