On Sunday afternoon I started to think about what I might print this week on my Tuesday letterpress printing day at Druckwerkstatt. I had an idea that I wanted to make a simple alphabet book, both to try out the geometry and spacing of printing a book that could be cut and folded from a single print on a single sheet, and also because I love the collection of wood type that the studio has, and I’m eager to take it out for a ride as much as I can.

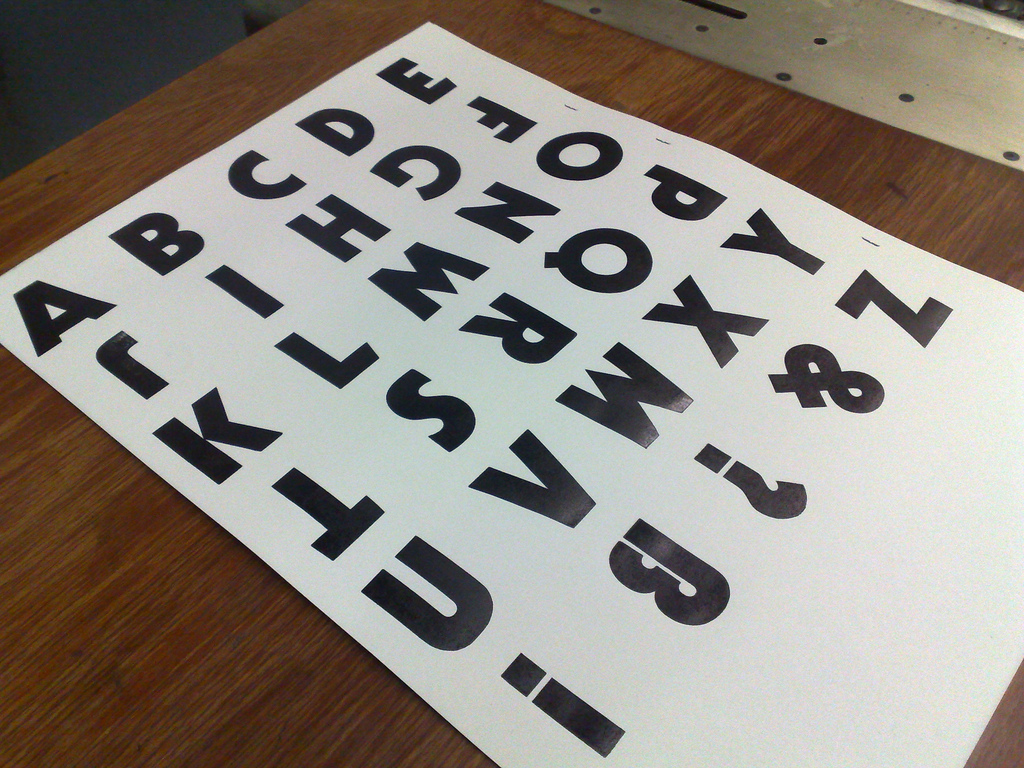

You can see where my imagining led me in the bottom of this photo: there’s a little paper mockup I made from a scrap of paper that shows how, by arranging alternating rows of letters right-side up and then upside-down, and making a few cuts and folds, I could achieve what I wanted.

Also in this photo you see the wood type I started to assemble in the studio to see if this would actually work. Fortunately, under a pile of paper in the corner of the shop, I found a really nice sans-serif face with every upper case letter present.

What followed amounted to 90 minutes worth of jig saw puzzling: I needed to find a way of arranging the letters on the bed of the proof press so that they were evening spaced and each centered in their own box. To do this I divided a 30cm by 36cm piece of paper into a grid of 6cm by 6cm squares, placed this sheet on the bed of the press, and then arranged the letters on the grid:

I found, to my surprise and delight, that a piece of 24 point spacer placed between each letter handled the “up down” spacing perfectly (all except for the letter Q, which had a descender so needed special handling). For “right left” spacing I simply using spaces as required, eyeballing the centering inside the squares penciled on the guide sheet. It took a while to get everything just right, and more than a few test prints to get it all really just right, but in the end I was very pleased with the result.

Once I’d perfected the layout, I spent another hour or so on makeready – making sure every letter printed equally black – and getting to understand the right amount of ink to roll onto the letters for a good print (the proof press is only partially working, so the inking, which would normally be handled automatically by the rollers on the press, had to be done manually for every print pulled, using an ink brayer).

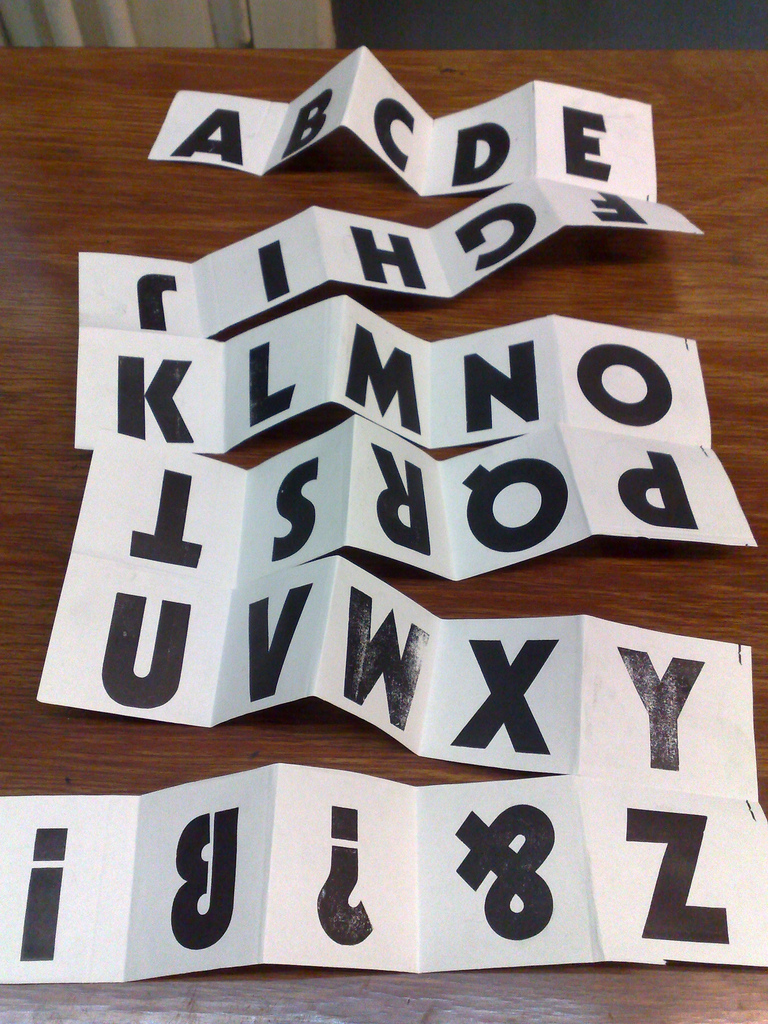

Once I had a good print ready, I ran it through the press again between two blank sheets of paper to “quick dry” the ink, and then manually folded and cut to match my original mockup:

Magically, when I folded it all together, it actually did make a book. You’ll have to imagine that, though, because in my reverie I neglected to take a photo.

After making 40 prints – which took about an hour because of the whole “ink the roller, walk across the room, ink the type, print, walk print over to the drying rack in the hall, repeat” process – I took lunch and then returned to see what I could do about getting the printed pieces ready for my subscribers to turn them into a book.

In the book bindery down the hall there’s a giant paper cutter that I used to trim the excess off the right and bottom of each print:

Next I needed to fold the prints along the 6cm by 6cm lines surrounding each letter. Fortunately, right beside the cutter I found (and figured out how to use) a machine purpose-built with this in mind, a “scoring machine”:

After a few sacrificial runs to figure out how the spacing worked, the machine made quick work (well, quick work times 40…) of the 9 scores on each sheet that needed to be made.

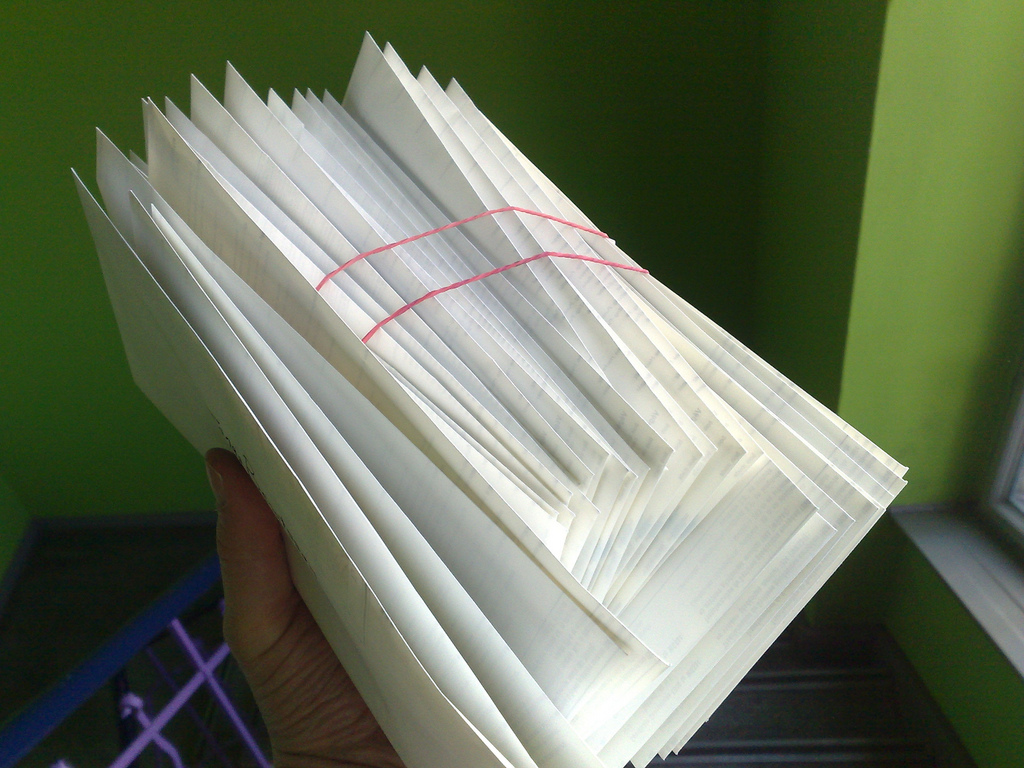

When I was all done I had 31 copies of this, ready to fold and mail:

On the way home I stopped in at the Grúne Papeterie, an excellent stationer on Oranienstraße and picked up 50 envelopes recycled from topographic maps and once I got home I spent an hour hand-addressing an envelope to each of the 31 subscribers.

This afternoon I folded each print along the scored lines so that it would fit in a small envelope, and when I was done this, here’s what I had:

To my surprise and delight, to mail a thick envelope like this anywhere in the world costs only 75 cents, and so a visit to the post office and €23 later, the alphabet-books-to-be were in the mail to Taiwan, Sweden, Denmark, England, Germany, the USA and Canada. I’ll be emailing subscribers a little more detail about the “how to turn this into a book” process shortly.

I am

I am

Comments

Thanks for the the step-by

Thanks for the the step-by-step. I missed out on being a “subscriber” but would love to see a picture of the recycled-topgraphic-map envelope. I’m a bit of a stationery junkie and I’m curious as to how it was made.

There’s no “closing date” for

There’s no “closing date” for subscriptions – just go here and sign up and you’ll get something from one of the next 3 weeks of printing!

Love the process and the

Love the process and the photos…too bad we cannot smell the ink or hear the press.

Not quite smell, or the

Not quite smell, or the entire process, but here’s a sound:

<iframe width=”480” height=”390” frameborder=”0” allowfullscreen=”” src=”http://www.youtube.com/embed/a…“></iframe>

thanks! ( :

thanks! ( :

Got ours! Awaiting

Got ours! Awaiting instructions.

I’ve put together a page on

I’ve put together a page on how to assemble the print into a book. Sorry for the delay!

Add new comment